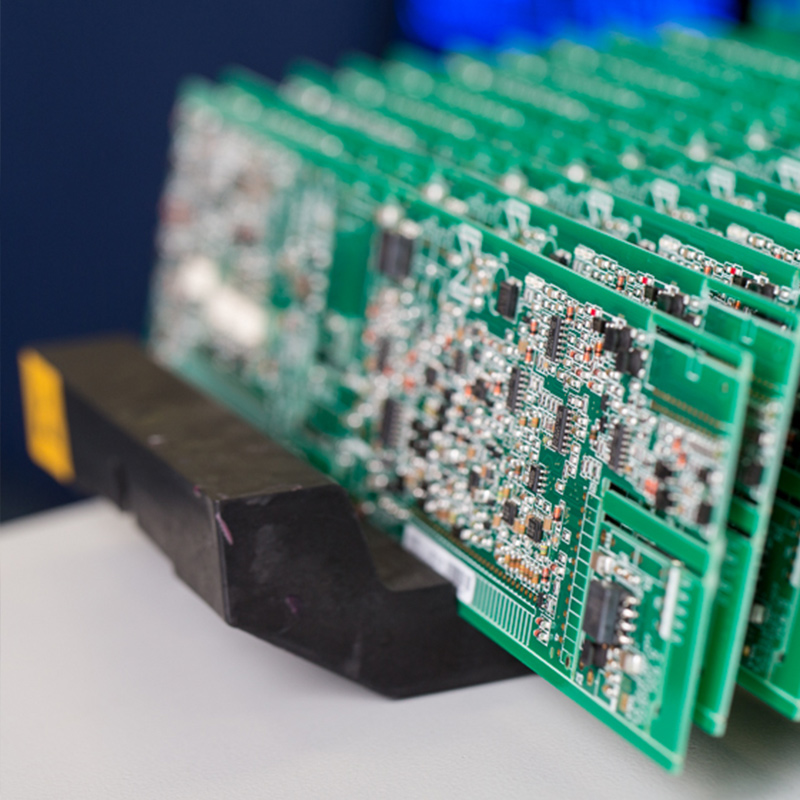

SMD Assembly

In our SMD assembly (Surface Mounted Device) we fabricate around 20 million components per year. Aided by vapour phase soldering this is particularly gentle and reliable. Usage of lead free soldering paste also guarantees our compliance with the RoHS guidelines of the EU. Air-conditioned rooms also ensure a consistent printing and production process.

We have three automated production lines equipped with automatic placing machines. These automated circuit board assemblers guarantee a high quality electronic manufacture. These automatic placing machines use a collect-and-place system and save significant time in the manufacturing process.

The SMD technology enables the components to occupy significantly less space, enabling us to use the smallest circuit boards and achieve a high component density. In this way the SMD assembly miniaturises the circuit boards, saving costs. Every circuit board is identified with a unique serial number allowing material tracing. Quality is assured by a final testing of all boards using automatic optical inspection (AOI).

Moisture sensitive components (MSL – Moisture Sensitivity Level) are stored after assembly in evacuated Dry-Shield Bags. Thus, we can guarantee that the quality of the components used in a later production charge remains to our standards.

- Rapid device manufacture using Collect-and-Place

- High quality through automated circuit board assembly

- No contamination

Contact form

You need further information or an individual offer? Then we look forward to your contact.

A member of our sales team or one of our representatives will answer you as soon as possible.