Fuel Cell Stack Durability Test

Aging test

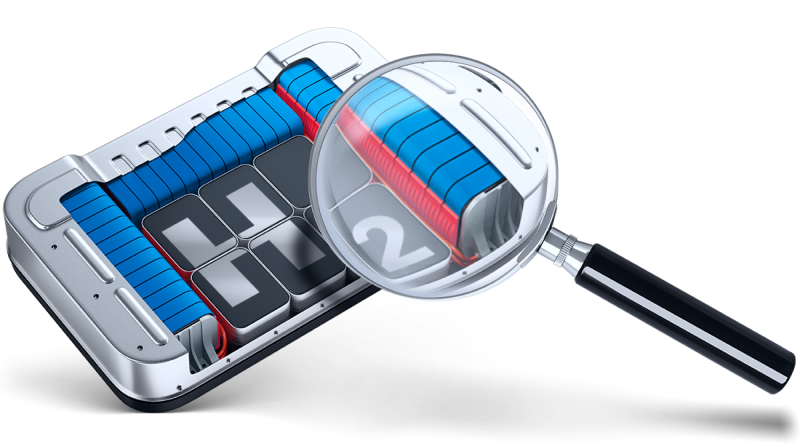

Being the active energy source in all kinds of application, it is always necessary to perform the durability test on fuel cell in order to ensure product safety and stability. In general, automotive standard requires 5,000 hours (~7 months) and stationary storage application even requires more than 10,000 hours.Step and triangular potential cycles are commonly used for shorten the long durability test time. However, it would be still a huge operating cost for a typical 100kW fuel cell stack system.

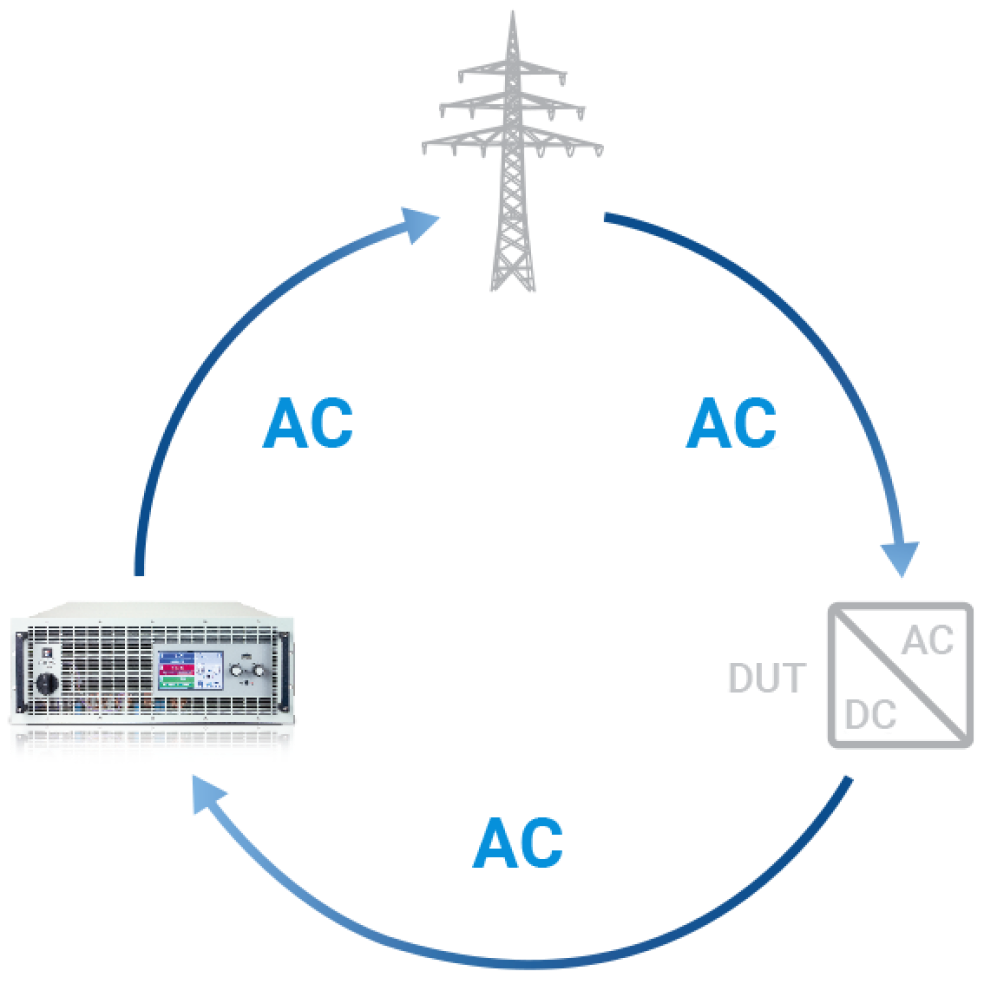

In order to optimize the energy usage, more and more fuel cell test stations are now equipped with regenerative DC electronic load for recycling the energy to grid, as well as returning the operating cost to factory owner. EA Elektro-Automatik electronic load series, EA-ELR 10000 4U, offers high regenerative efficiency that could save energy and cost.

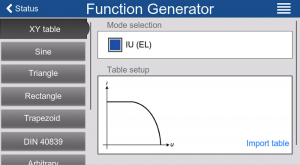

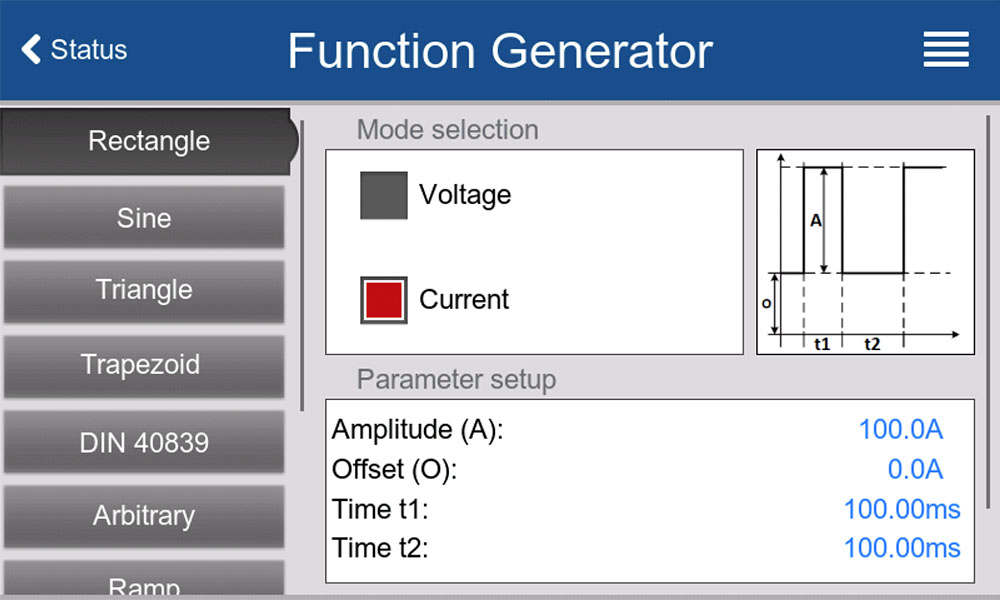

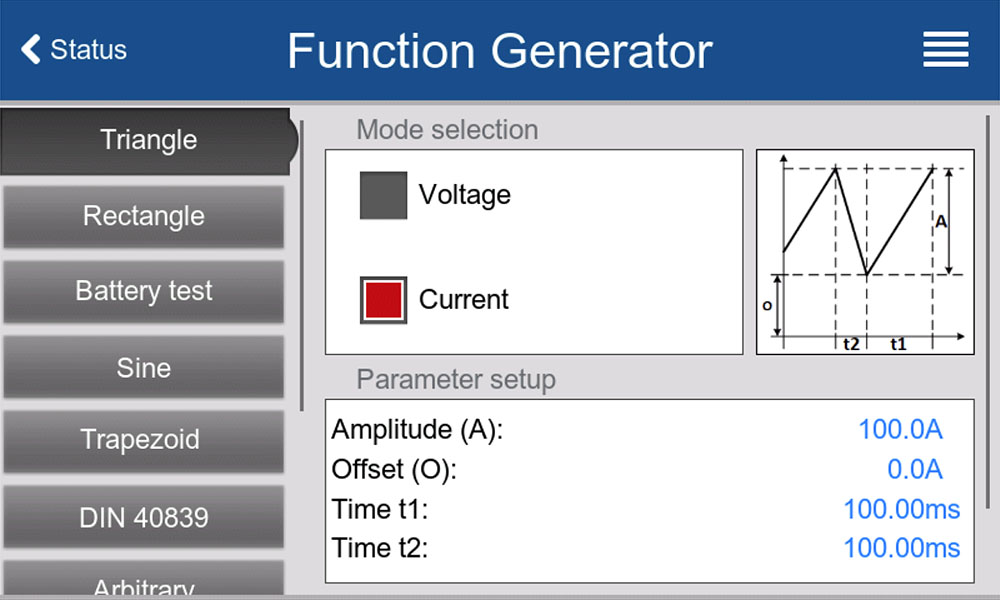

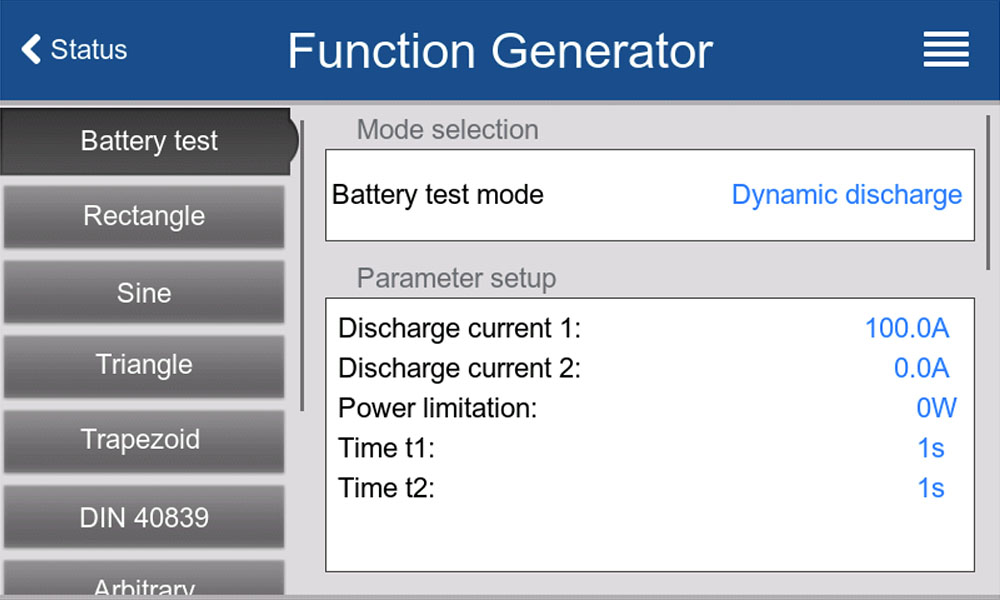

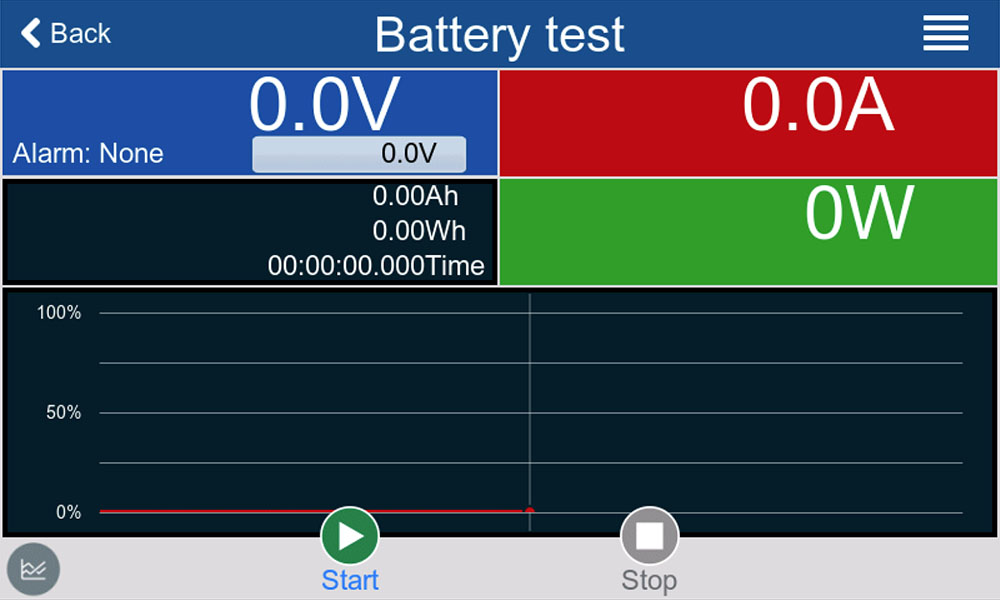

Moreover, user can perform accelerated test profiles (step or triangular) by the internal Function Generator in ELR series. Discharging Test function could provide the accumulated energy measurement result in addition.