Faster Tests

For battery systems in vehicles

The electrification of vehicles has pushed past consumer passenger cars into commercial and industrial transportation forcing automotive electronics to constantly evolve. While this technology area was once focused on entertainment, navigation, and comfort systems the industry has now turned its focus to higher power, higher voltages, and energy management systems.

This power is not just localized to a battery and electric motor, the drivetrain and power management systems also have similar power requirements. To be able to keep up with the changing demands of electric vehicles, the challenge for test engineers is to keep up with the trends and avoid buying new test equipment every few months.

EA Elektro-Automatik’s line of DC power supplies, electronic loads, and bidirectional power supplies have features that allow flexibility to test multiple devices and still meet future needs. EAs PSI, EL, ELR, and PSB product series can go up to 2000V, have true autoranging and on-board arbitrary waveform, and function generator.

This flexibility allows EA to produce or sink power needed to simulate or test any power device in an electric vehicle and the arbitrary waveform generator enables the user to simulate real-world conditions.

See Our Specific Automotive Test Solutions Below for more Details

Application Solutions

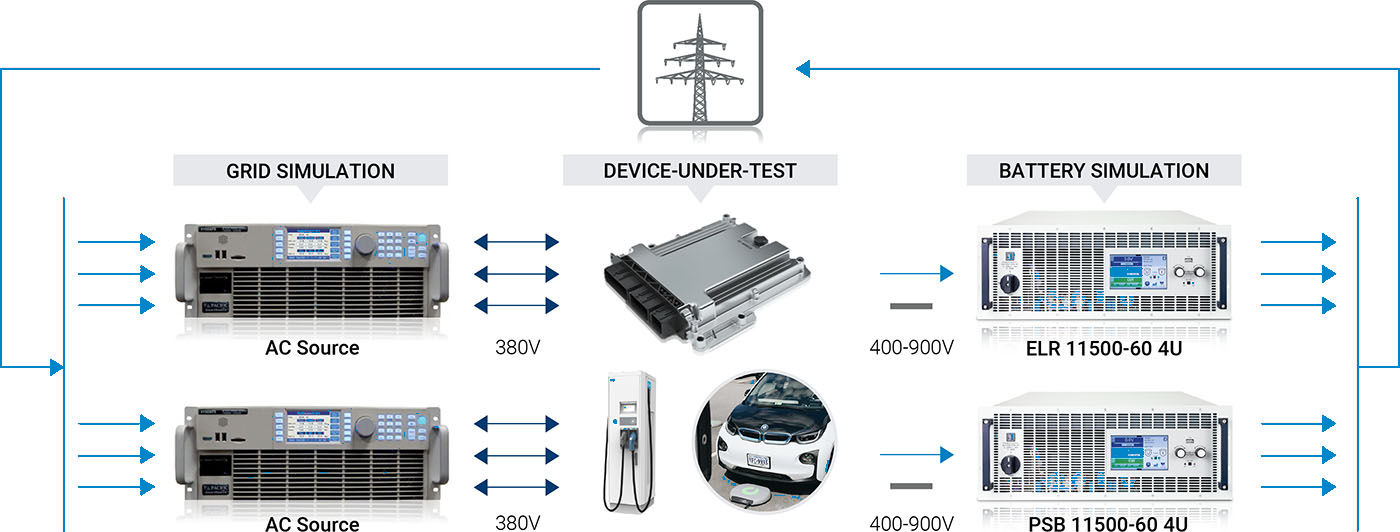

Charge System Testing

On-board chargers(OBC), Plug in charging systems and wireless chargers

One of the main questions when deciding to purchase an electric vehicle is how and where it will be charged. This question has the auto industry moving forward with different charging concepts to reduce the impact charging has on the driver. The trend appears to be moving towards higher voltages that requires smaller currents and less copper. While the industry decides on standards, testing of these concepts requires a versatile power supply that can meet low and high voltage requirements many of these chargers have.

EA’s line of DC power supplies with Autoranging capability can meet these changing demands. Autoranging allows the user to get full power over a wide voltage range, rather than just at max voltage like traditional DC power supplies. EA also offers 1000V, 1500V and 2000V models that features high power density, bidirectional capability, function generators, regenerative capability, and very low EMC emissions to meet the ever-increasing requirements for EV charging systems.

EA Advantages:

- Autoranging

- Power Density

- Battery simulation

- Bidirectional and regenerative

- Arbitrary waveform and function generator

- Low EMC

- Output voltage up to 2000V

- Plug and play paralleling

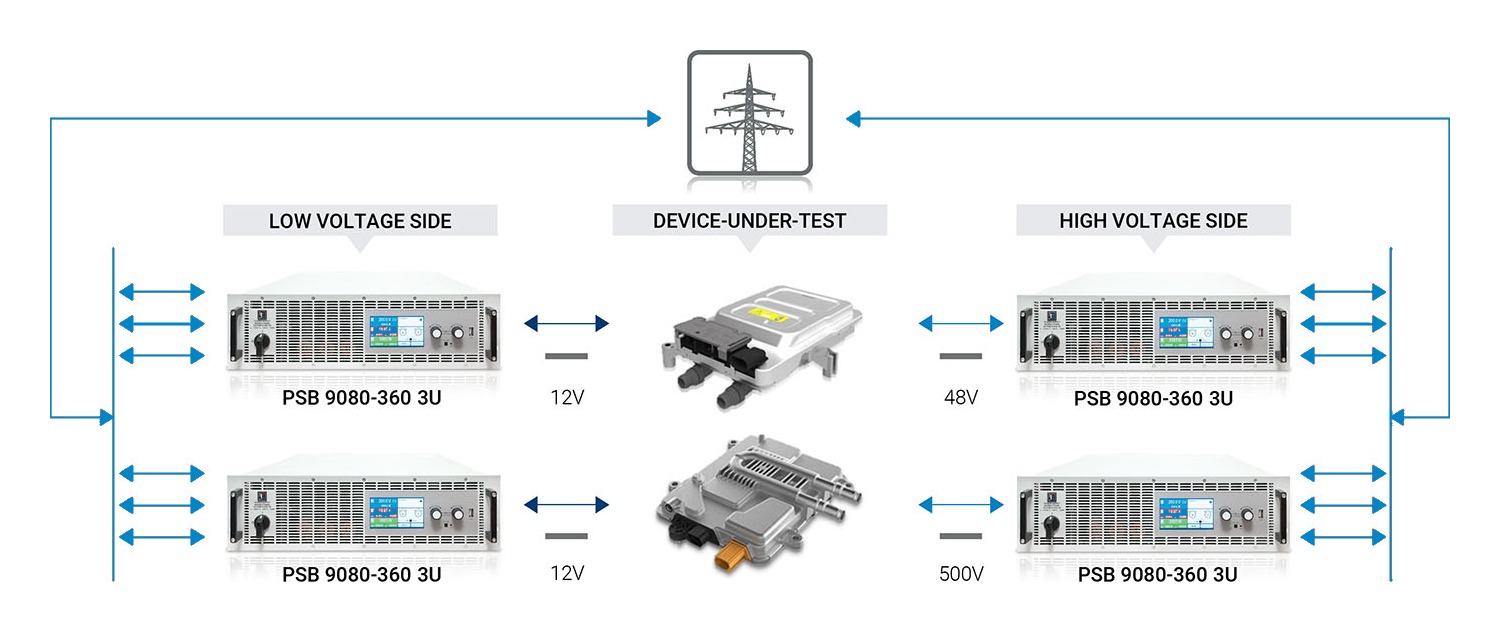

DC-DC Converter Testing

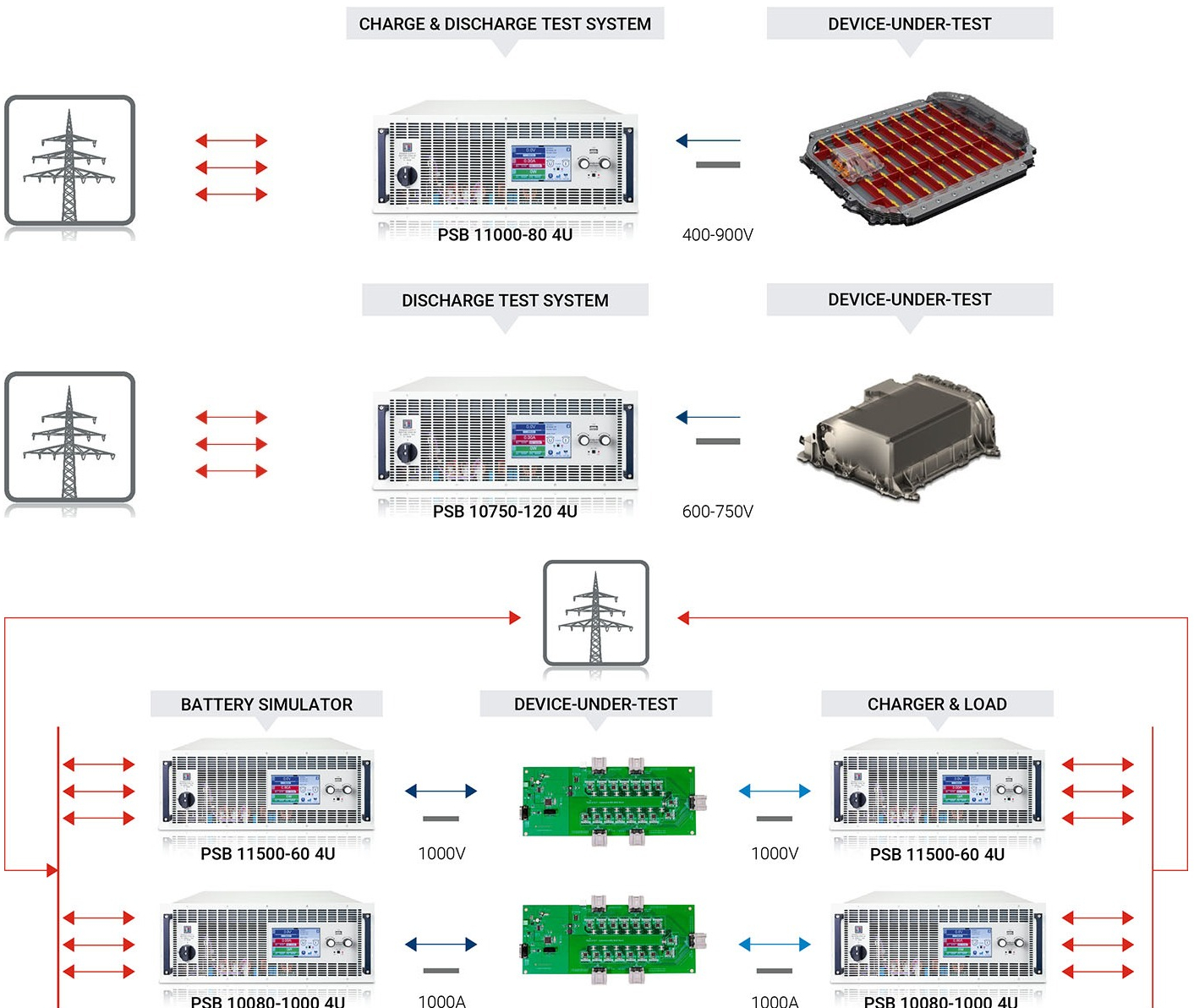

DC to DC converters in electric vehicles are used to convert battery voltages (200-800V) to different DC voltages (12-48V) used by the headlights, radio and other ancillary equipment. Testing these devices requires a DC input and a load to connect the DC output to. EA’s line of power supplies and loads have low and high voltage options to meet these needs. EA’s bidirectional power supplies, the PSB 9000 and 10000 series can be used to source or sink voltage, enabling the test engineer to provide power both ways and minimize the test equipment needed.

The built-in function generator can be used to test real world situations, such as the headlights turning on and off repeatedly or turning on the heater full blast in the middle of winter. Figure 2 shows a typical test set up using a pair of PSBs to test both sides of the DC to DC converters. Due to the high efficiency of the PSBs, only 5-10% of the power is lost during these tests, with the remainder of the power regenerating back to the local power grid.

EA Advantages:

- Autoranging

- Power Density

- Battery simulation

- Arbitrary waveform and function generator

- Low EMC

- Output voltage up to 2000V

- Plug and play paralleling up to 2MW

- High efficiency up to 96%

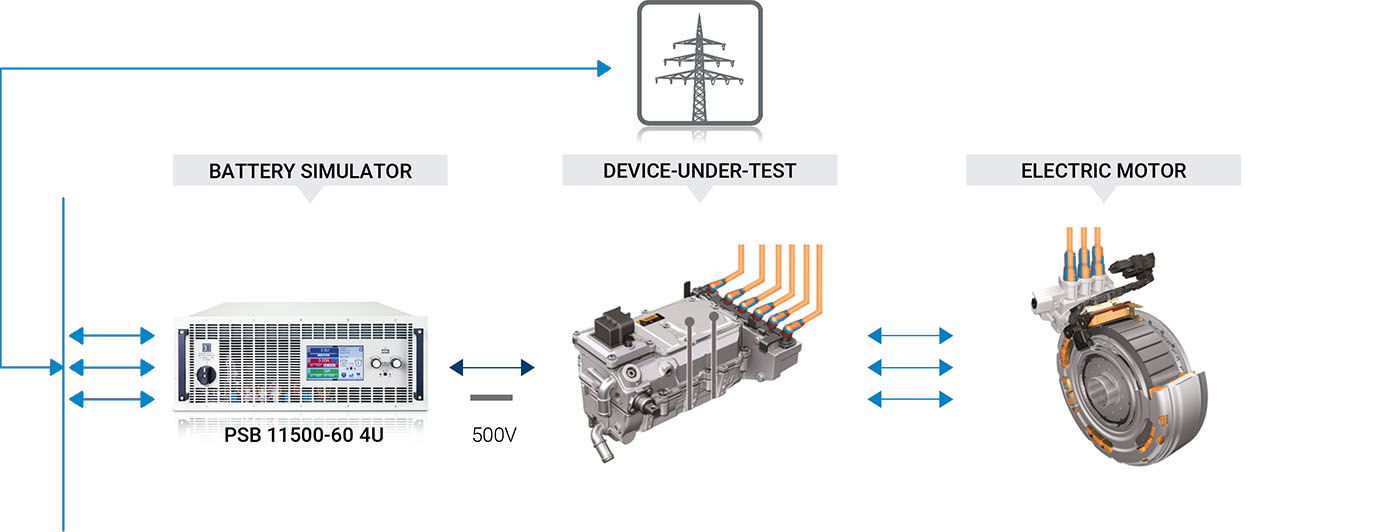

Traction Inverter Testing

In electric vehicles the motors are driven by AC current, but the majority of the vehicle is powered by DC. This makes sense since the source of power is a battery. To mitigate this traction inverters are used to convert power back and forth from battery and motor. Traction inverters are also used to support regenerative braking, boosting voltage and switch protection. Figure 3 shows one application of EA’s bidirectional PSB supplies being used to test a traction inverter (device under test) that is being driven by an electric motor.

The PSB can both supply power to the traction inverter while simulating a battery and sink power when the motor turns into a generator to charge the battery during braking. EA’s autoranging feature provides a flexible output range compared to traditional DC power supplies making the full power output available as the voltage output decreases. What that means is EA’s DC power supplies and loads can replace several traditional DC supplies that are normally needed to cover the higher voltage/lower current and low voltage/higher current operating points of the traction inverter.

EA Advantages:

- Autoranging

- Power Density

- Battery simulation

- Arbitrary waveform and function generator

- Voltage models up to 2000V

- Low EMC

- Plug and play paralleling up to 2MW

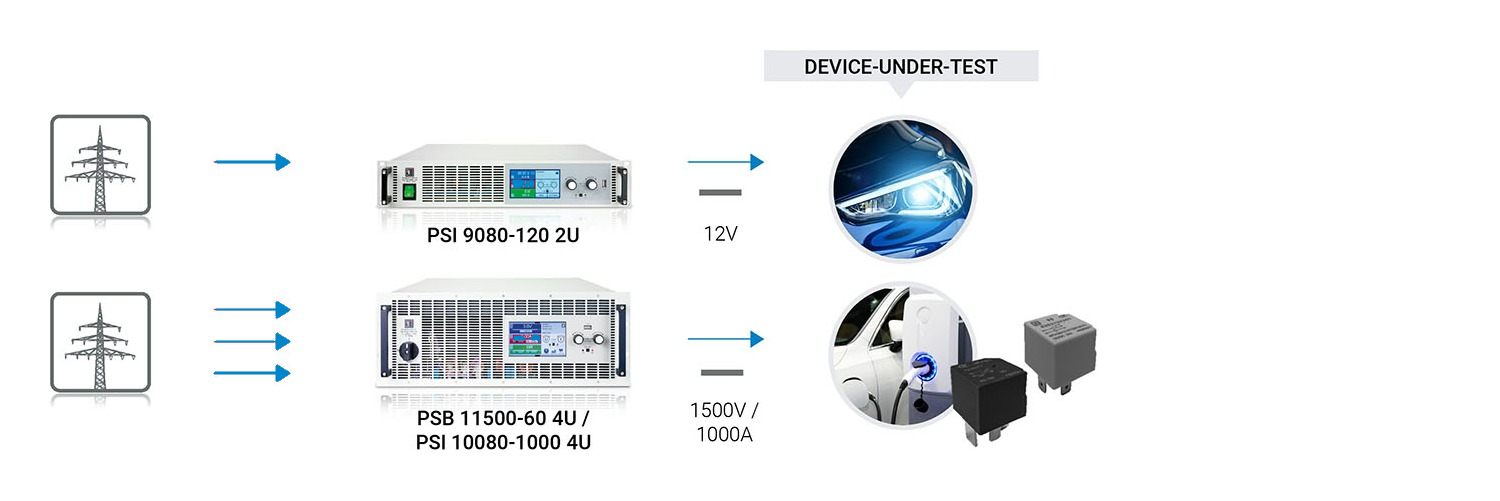

Lights, Relays, Sensors and Accessory Testing

In addition to the major components of the electric vehicle, there are many other components in both EVs and combustion engine vehicles that also operate using DC power. Like many of the components in a vehicle, the voltages needed to power them can vary from the standard 12V up to 1000V or more. With so much variety test engineers are forced to acquire several traditional DC power supplies to test everything. EAs DC supplies and loads use a combination of high power density and autoranging to cover a much wider operating range and ultimately saving valuable rack space and cost. If cost is an important factor in your decision,

EA’s extremely high efficiency can save $1,000 or more per year just in energy costs. Integration into an ATE is also simplified by using Anybus modules for digital communications with options such as CANopen, CAN, Ethernet, Profibus and more.

EA Advantages:

- Autoranging

- Power Density

- Battery simulation

- Arbitrary waveform and function generator

- Voltage models up to 2000V

- Low EMC

- Plug and play paralleling up to 2MW

Fuel Cells, Batteries, and Battery Management System Testing

The power source for electric vehicles are batteries, fuel cells and battery management systems. With so much demand for power in all parts of the vehicle, it is imperative that batteries and fuel cells are tested by simulating real world conditions. Starts, stops, rush hour traffic in 100 degree heat with the AC are all situations the EV will encounter on the road and the ability to recreate these scenarios is required to meet various automotive test standards.

The built-in function and arbitrary waveform generator in EAs DC power supplies, loads and bidirectional DC supplies simplifies the process of simulating various driving conditions. Battery test features are also included to automatically charge or discharge a battery. The bidirectional capability of EA’s PSB series can accurately simulate a battery to test battery management systems without having to wait for a battery to charge or discharge to a specific state of charge.

EA Advantages:

- Autoranging

- Power Density

- Battery simulation

- Battery and fuel cell test functions

- Arbitrary waveform and function generator

- Voltage models up to 2000V

- Low EMC

- Plug and play paralleling up to 2MW

Case Studies

PSB 9000 for LV 123

Automotive Test Standard for BMW, Audi, Daimler, Volkswagen and Porsche

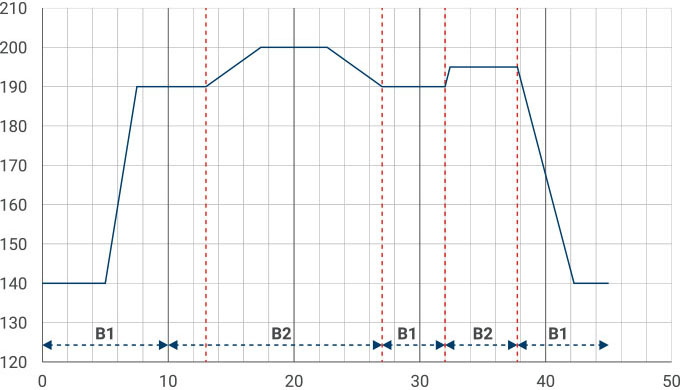

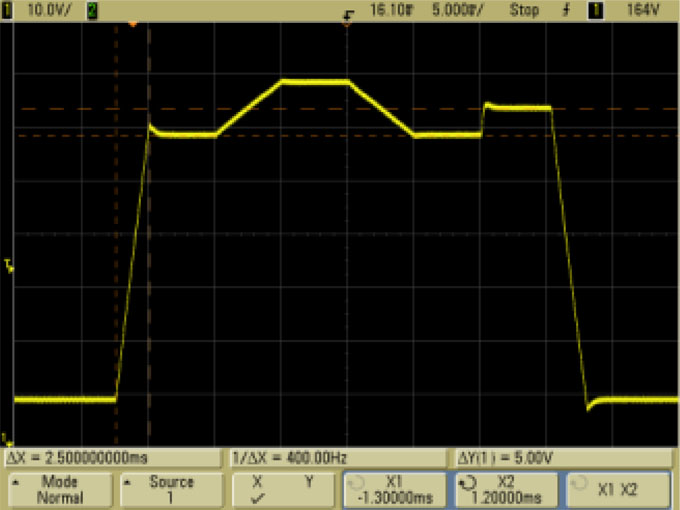

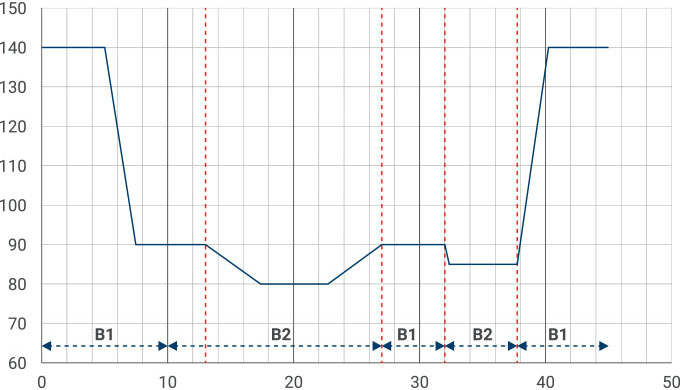

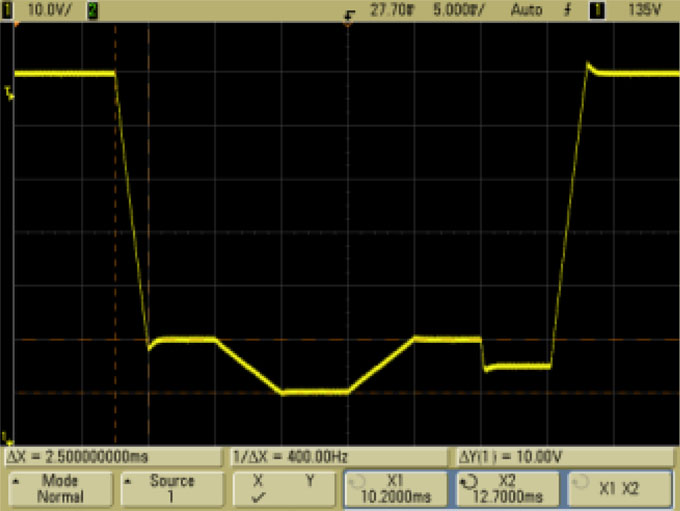

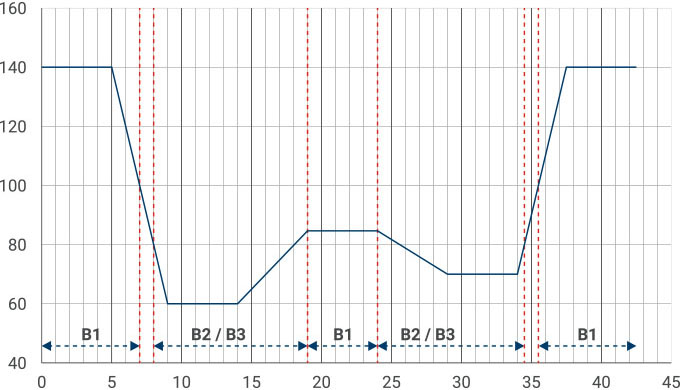

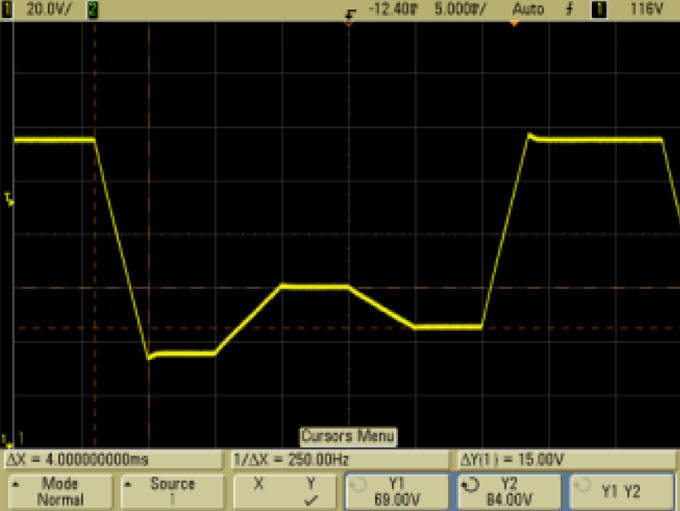

LV 123 is a test standard developed for German automotive OEMs that tests electrical characteristics and safety of high-voltage components in road vehicles. The tests are designed to put electrical components in road vehicles in situations where the input voltage or demand is lower or higher than normal to ensure the device can continue to operate. These are similar to the extreme real world conditions the devices may encounter during operation. The test engineer’s job is to reproduce the waveforms or test sequences to ensure the device will continue to operate. With EA’s built in arbitrary waveform and function generator, the user has all he needs to program precise waveforms that recreate the test requirements put forth by the LV 123 standard.

In this case, a PSB 9000 series bidirectional DC power supply was used to recreate the test conditions outlined in the LV 123 standard. Below you can see three examples: the upper limit operating capability, lower limit operating capability and high limit operating capability. As you can see from the examples, the PSB easily reproduced the specified waveform with great accuracy. Normally this type of test is performed with a DC power supply and/or DC electronic load being fed by an arbitrary waveform generator to create the waveforms. The PSB can perform the source and sink functions required for the test as well as creating the arbitrary waveform. Being able to do all of this from one unit saves time, cost and more importantly complexity.