Precise tests of degradation behavior and efficiency

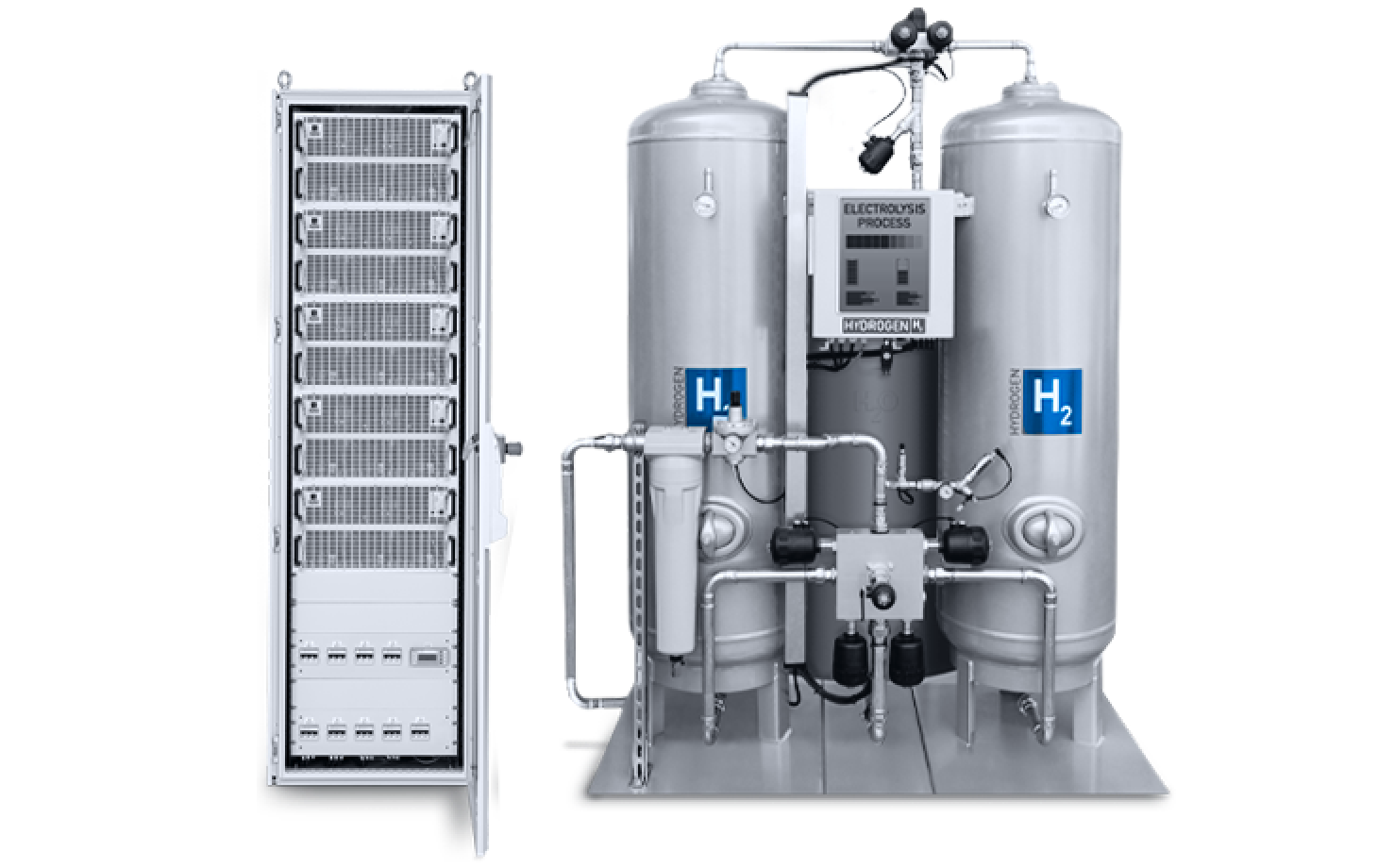

Dynamic tests provide valuable information about the behaviour of electrolyser stacks with different power supply qualities. EA offers the ideal power electronics for these tests – with fully controllable devices, high accuracy of the values determined and maximum flexibility when setting the parameters.

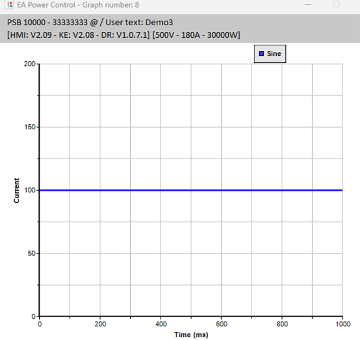

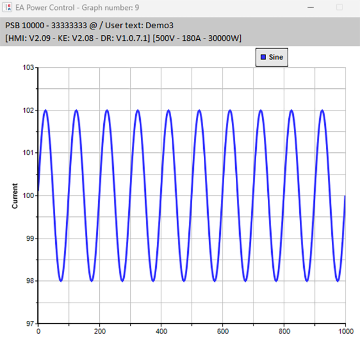

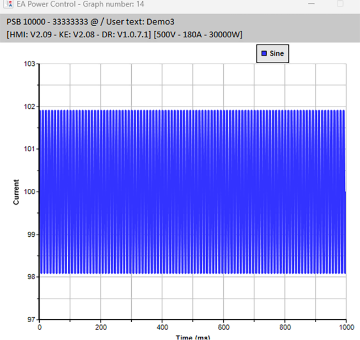

EA highlight: DC ripple in the integrated function generator

The superposition of a direct current with an alternating current can be set using the function generator.