Battery Powered trains

Trains are about to go green

For most of a century trains are powered by electrical propulsion, now we can finally realize long distance travelling by battery-electrified trains. Not only the demonstration projects, more and more companies are putting R&D resources to battery-electrify our most important mass transportation. Battery-electric train has no or limited overhead lines for minimizing infrastructure investment, furthermore, it provides a much more quite operation for a more comfortable environment for travellers. Like electric vehicles, we need a new test scheme for all new power electronics components on the new battery-electric train.

EA Elecktro-Automatik, the leader of Europe DC power solution, offers the right and state-of-the-art solution for the coming new era on locomotive. PSB Bi-directional power supply offers the flexibility to test D2D converters without using a real battery; PSI Programmable DC power supply provides the rich waveform generation in order to fulfil the standard EN 50155-2017; ELR Regenerative DC load is the best power density for battery life testing for both Li-ion and fuel cell technology.

Products Used in Railway Technology

Application Solutions

Battery Simulation

Li-ion and Fuel Cell Battery Simulation

Fuel cell offers a stable and high capacity power for long distance travelling range, with the support of Li-ion rechargeable battery, this hybrid solution realizes the future of battery electric-trains. Optimalization the energy flow between fuel cell, Li-ion and DC-DC converter would be a challenging task for engineers. To conduct different scenario test cases, a programmable and configurable battery simulator could simplify the test time and shorten time-to-market.

EA Advantages:

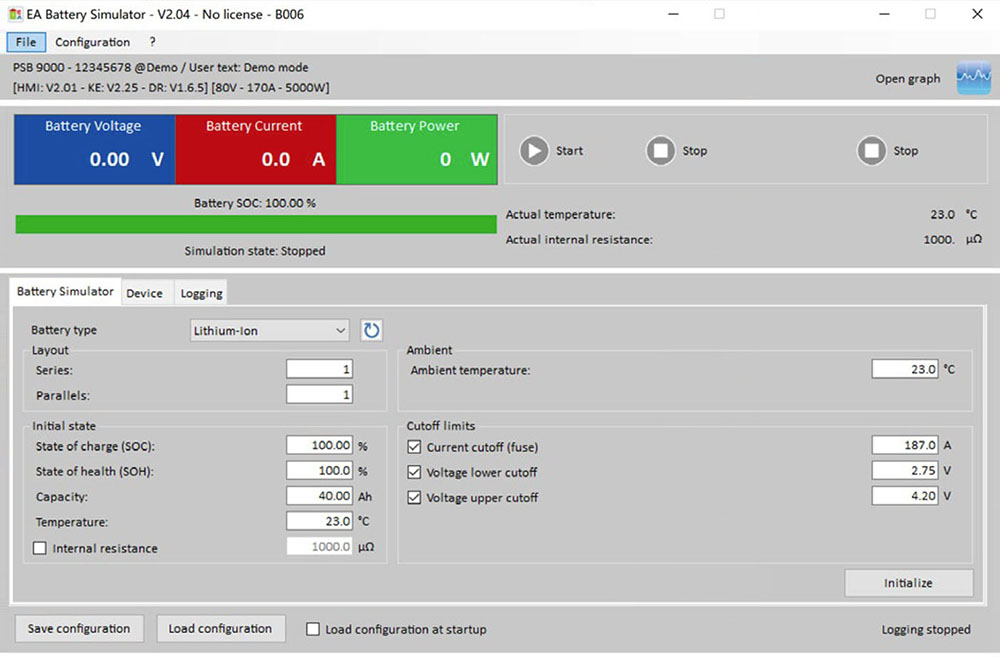

- Li-Battery & Lead Acid Battery Simulation Models (Including SOC and SOH user parameters)

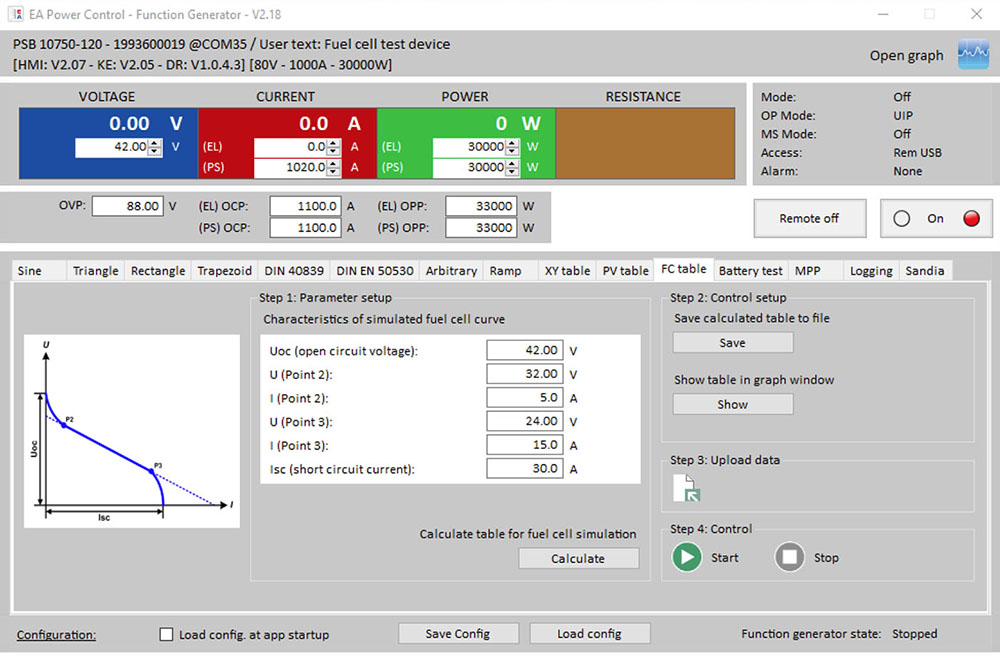

- Fuel Cell Simulation

- Wide voltage range, from 60-2000V

- Highest Power Density in industry, 30kW / 4U

- Modular design for flexible power expansion and ease of maintenance

- Regenerative for high power testing

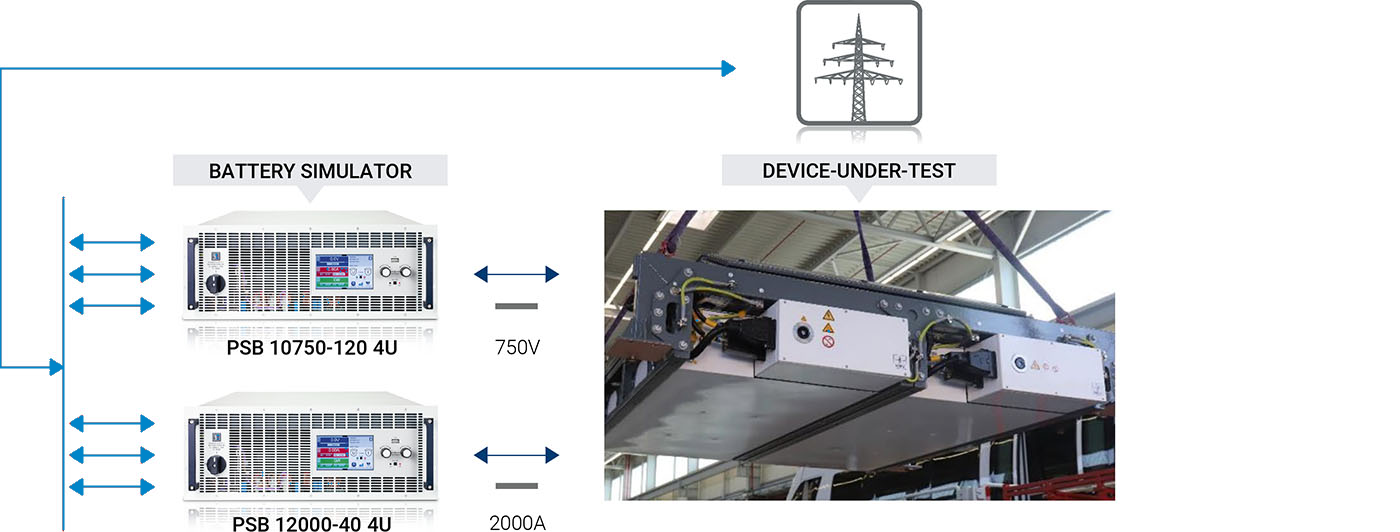

Typical Test Setup

Fuel Cell Simulation in EA PowerControl

Battery Simulation in EA Battery Simulator

DC-DC Converter and Dynamic Charging

Auto-ranging with Bi-directional feature

Not only your mobile phone needs charging, we need to charge the train also.

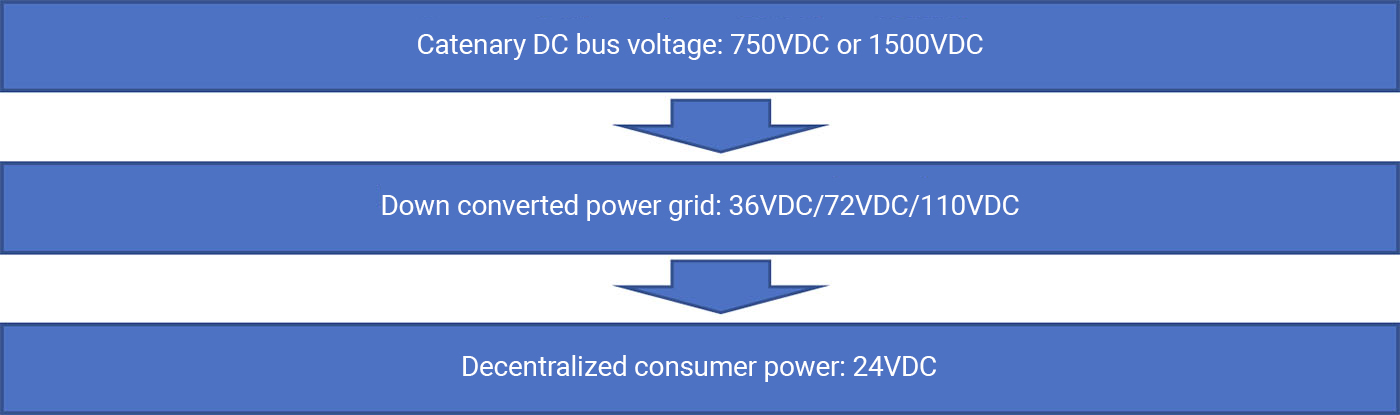

Below is simplified power distribution diagram inside a train. We have battery charger, DC-DC converter, DC-AC inverter and consumer circuitries (e.g., lighting and air-conditioning). We need a wide range of DC programming power supplies to fulfil the test on verifying the locomotive power modules can operate under extreme temperature and mechanical conditions.

EA Advantages:

- Autoranging output for saving unit cost

- Regenerative feature saves cost on endurance test (reduce the electricity cost)

- Built-in function generator for user defined waveform such as EN 50155-2017

Case Studies

High Performance Tests with High Dynamics – Reallife example

of a test rack

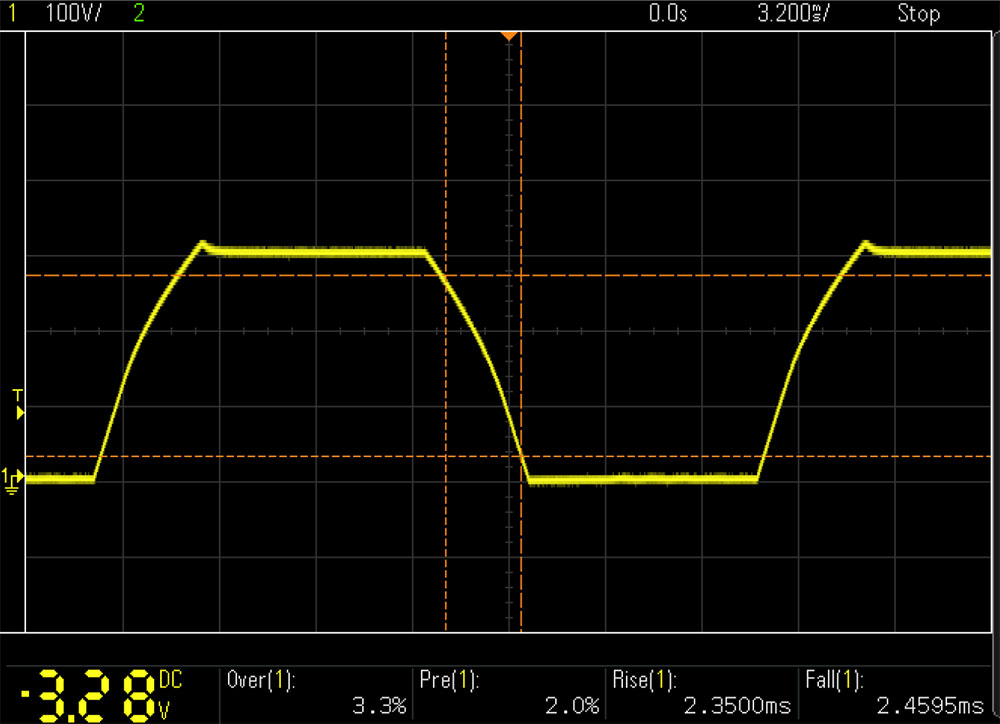

A battery-electric train always requires a high-performance test environment with a highly dynamic output capacity of DC power supplies. With regard to the EN 50155-2017 standard, D2D converters in battery-electric trains have to operate under a certain amplitude in the normal state.

In addition, similar voltage fluctuation tests are also required for the main power modules in the train. Bidirectional power supplies from EA offer not only a compact power rack (240kW/42U) but also a flexible function generator for the user to transmit different waveforms of the test voltage.

Waveform of the voltage fluctuation (300V/2,5ms, no load condition)

A ripple of 60Hz at 220Vdc offset (no load condition)

An Example of a 180kW Power Rack:

- Source mode: (from top to the 3rd unit)

1000V/240A/90kW - Sink mode (from the 4th to the lowest unit)

1000V/240A/90kW - Full Load Verification

Source and sink interconnected

450V / 200A / 90k

An example of a 180kW Power Rack

Result