Regenerative Loads

The economically and ecologically sensible alternative to conventional loads

The new series of electronic DC loads with energy recovery offers new voltage, current and power ratings for a variety of applications. These devices include four common operating modes: constant current, power, voltage and resistance. In addition, the FPGA based control circuit provides additional features such as a function generator, which is simply a table based regulation circuit for the simulation of non-linear internal resistances. Even response times for the control via analogue or digital interfaces have been improved thanks to the DSP controlled hardware. There is one characteristic that despite making the loads applicable to higher power scenarios, it comes with a disadvantage.

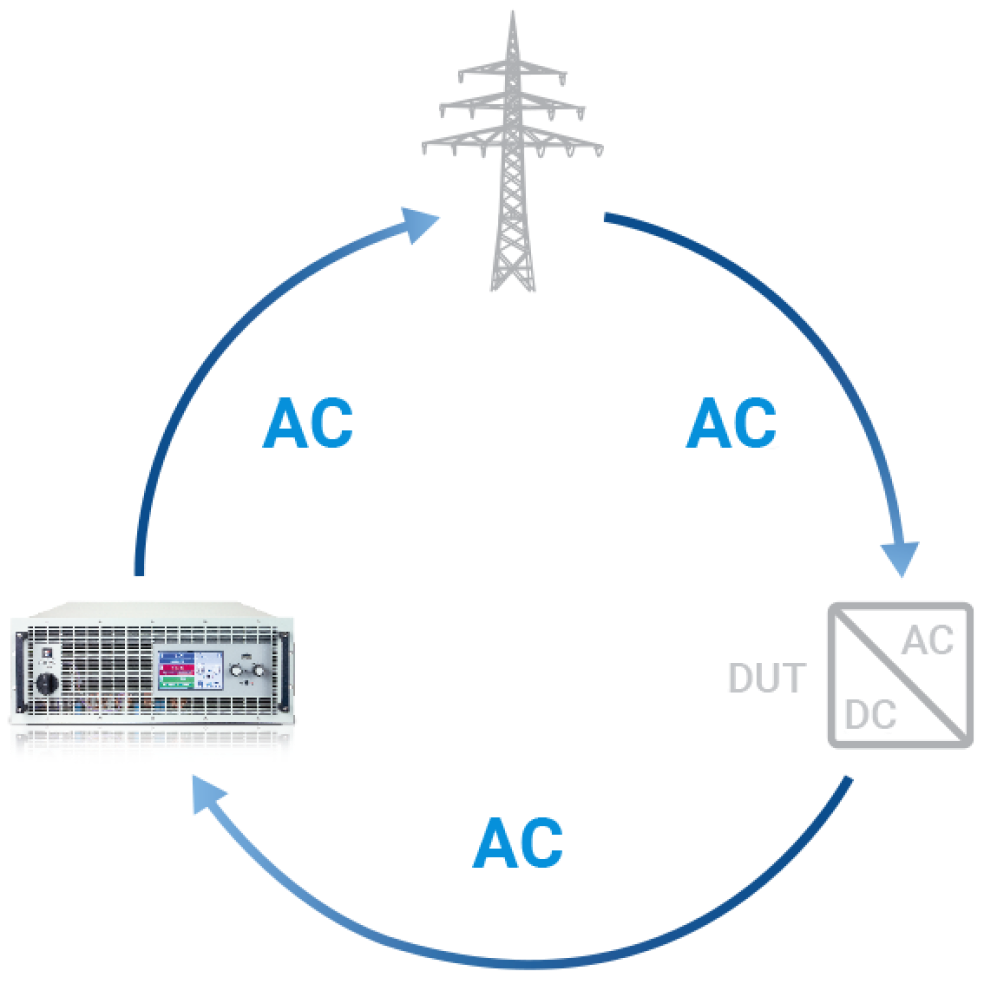

Multiple devices in the ELR Series are capable of operating in parallel in a master-slave configuration, which allows the user to parallel the loads for UUTs that might require higher power capabilities. This capability can be extended up to 480 kW in cabinets for a significantly higher total current, with the option to realize higher power capability upon request. However, as power levels to be tested increase, dissipating this energy may not be an attractive option for some customers, as this certainly implies a not so eco-friendly or ‘green’ approach.

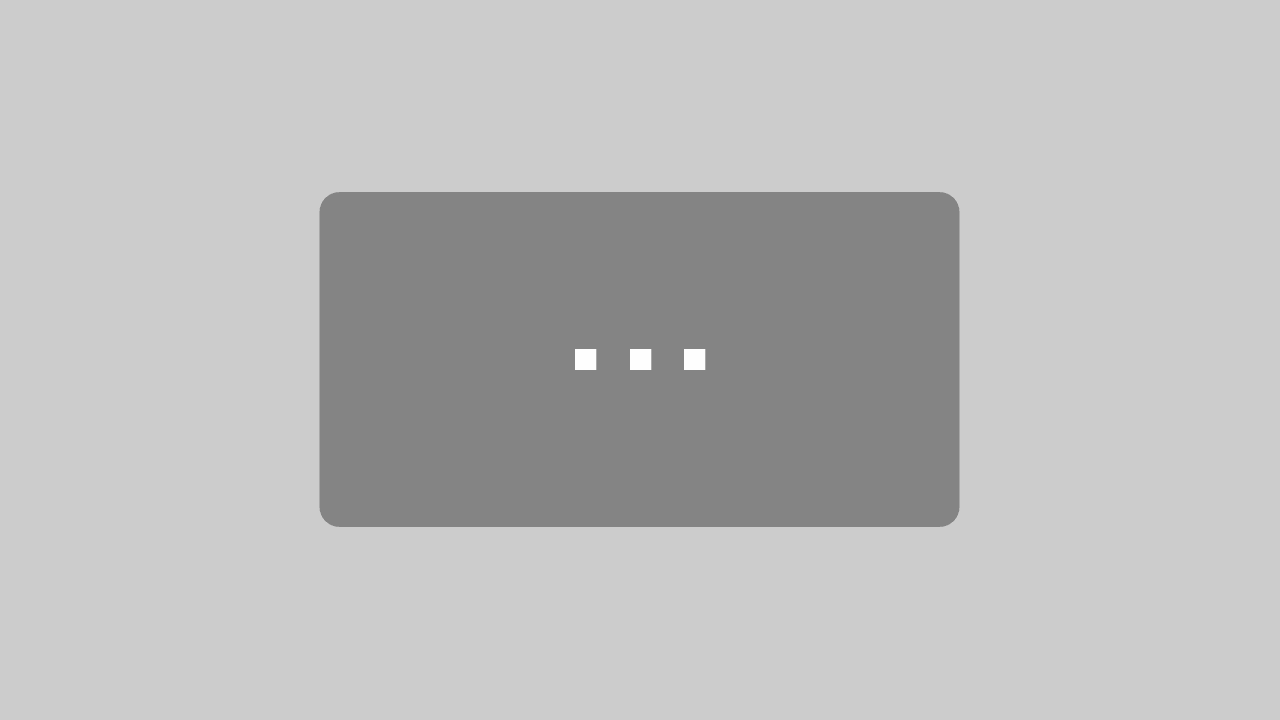

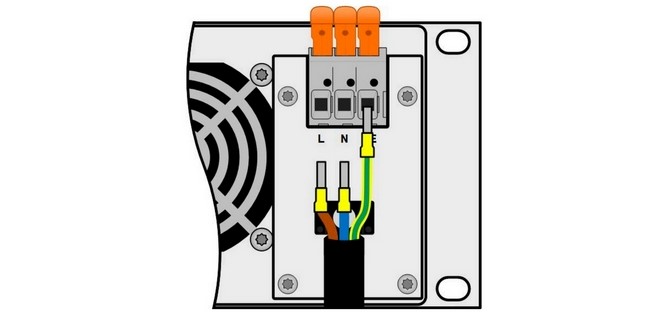

The solution implemented in these devices makes the loads to be known as regenerative or energy recovery loads. The most important feature of these electronic loads is that the AC mains connection, i.e. grid connection, is also used as output for the back-feed of the supplied DC energy, which will be converted with an approximate efficiency of up to 96%. Energy recovering allows to lower energy costs and avoid expensive cooling systems, like the ones required for conventional electronic loads, which convert the DC input energy into heat.

Product series ELR with Power regeneration