The green ecosystem of aviation

Electric drives with green hydrogen

The electrification of aviation has begun: The world’s leading aviation and engine companies are moving towards an emissions-free future. Their goal: net-zero greenhouse gas emissions by 2050. To achieve this, the entire aviation ecosystem is being redesigned:

Aviation engineers are converting traditional combustion and kerosene engines into direct current electricity plants, powered by hydrogen produced in electrolyzers.

Contribution to the promotion of sustainable aviation

Experienced development partner to the aviation industry

Intensive work is being done on sustainable aviation, but the demands on electric charging and drive systems are high, both in terms of performance and safety standards and reliability. The new devices and systems are tested accordingly frequently. EA Elektro-Automatik (EA) develops the devices and test routines for future developments in the aviation industry

– and thus makes an important contribution to the promotion of sustainable aviation. In doing so, EA is contributing the experience gained from almost 50 years of development partnership for sophisticated power and test routines for aircraft, drones and unmanned aerial vehicles.

DC-electrified charging and drive systems

For the sustainable aviation of tomorrow, aviation engineers are developing completely new DC-electrified charging and drive systems to replace the DC and AC solutions currently in use – and are facing major challenges in the process.

- Energy supply and storage

Hydrogen and technologies for fuel cell battery management - Energy management

At take-off: clean, consistent energy In flight: moderate energy requirement - Energy conversion and distribution systems

For instrumentation, air conditioning, critical landing gear, wing control and braking systems - Weight and size

Of motors and battery systems - Withstand extreme conditions,

e.g. vibrations, temperature fluctuations, humidity, high acceleration/gravity - Hazardous materials,

e.g. lithium batteries and explosive hydrogen (liquid/gaseous)

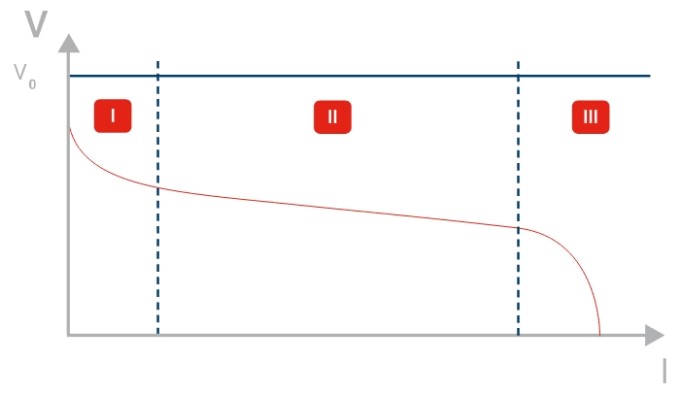

With the XY table mode, the IO power supply can simulate the output of a fuel cell, as shown here. By using the output characteristic of the fuel cell, the components connected to the fuel cell can be tested with different power characteristics of the fuel cell.

Sophisticated test routines for new devices and systems

Electrified drives have to be rethought, and every new device and system has to be extensively tested, first in development laboratories and then in flight. We are developing ever more powerful, energy-feeding devices for the strict test routines of aviation.

- Performance, reliability, electromagnetic interference and safety

- High-performance DC electric drive motors (electric turbines) with megawatt-capable peak output

- Heating/air conditioning, lighting, infotainment

- Heavy-duty landing flaps/brakes/landing gear

- Avionics instrumentation

- Battery capacity and efficiency for long-haul flights of fuel cells in combination with non-combustible battery boosters

Powerful EA power electronics with powerful features

The aviation industry uses power electronics from EA to test the power supply systems of the new electric drives.

The devices have power ranges from 320 W to 3.84 MW, voltage ranges from 0-60 V DC to 0-2000 V DC and current ranges up to 64,000 A DC.

Bidirectional power supplies with regenerative power supply 01

- Efficiency of up to over 96 %

- Fast amortization of the device

02 Electronic loads with energy recovery

- Simulation of a wide range of load and fault conditions

- Ensuring performance and response to fuel cell operating modes

Built-in function generator 05

- No external signal generator required

- For modulating the output of the power supply unit

03Real autoranging

- Full output power over a wide voltage and current range

- Ideal for testing a large number of devices

- Providing a DC power supply with lower power for a specific load requirement

- Less space required in the test rack

- Reduced cooling requirement

- Significant cost savings

- Simplification of the test system

04Energy recovery with efficiency of over 96 %

- Significant energy savings through grid recovery of the energy consumed

- Ideal for testing high-performance fuel cell stacks

- Operation with less waste heat

- Less space required in the test rack

- Reduced cooling requirement

- Significant cost savings

- Simplification of the test system

Built-in function generator 05

- No external signal generator required

- For modulating the output of the power supply unit

The EA application solutions for test procedures

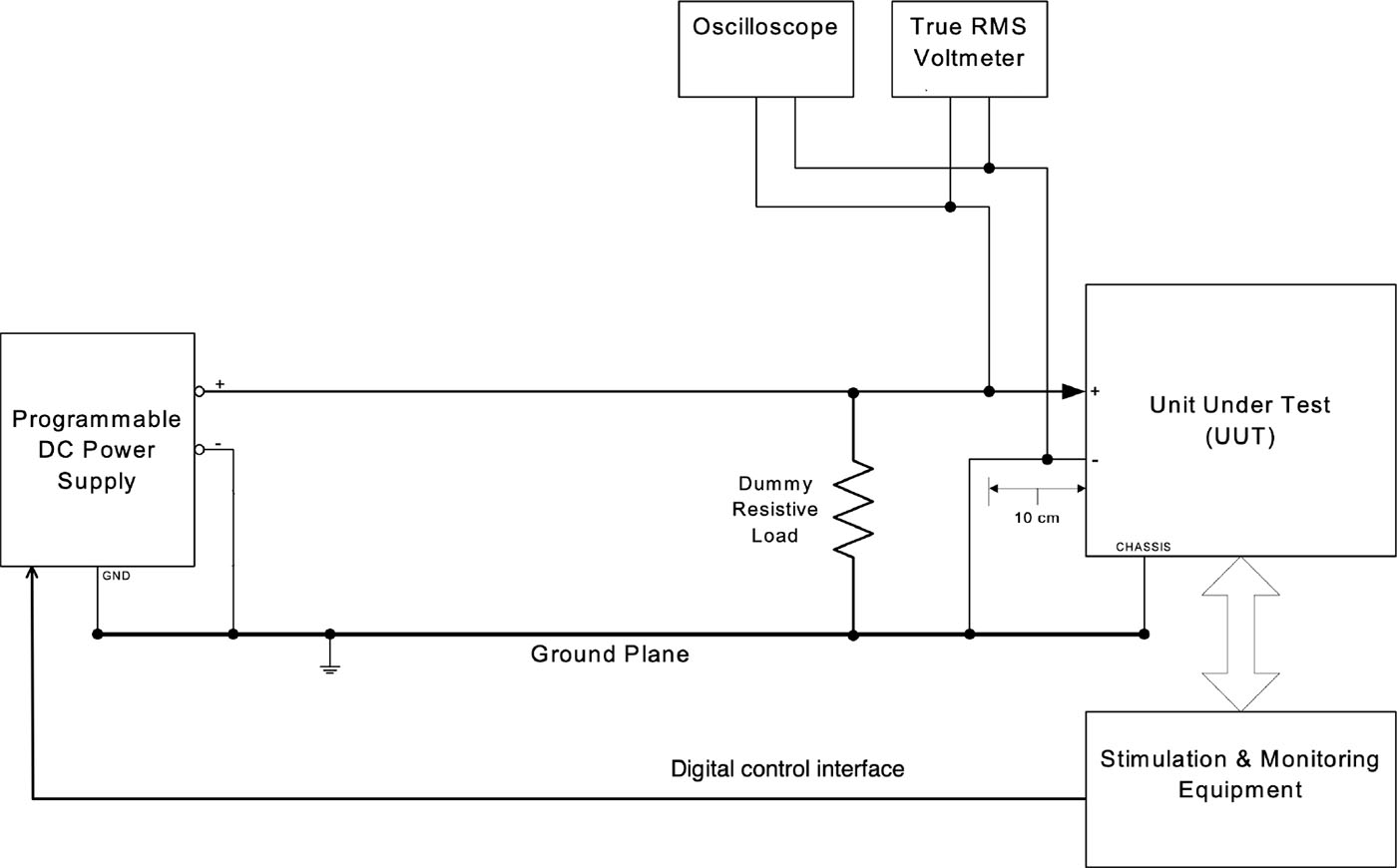

Numerous tests of aircraft electronics and other electrically powered devices on board an aircraft are intended to show whether the devices can withstand overvoltage and undervoltage conditions, power failures and voltage transients. MIL-HDBK-704-7 and MIL-HDBK-704-8 describe the test methods and procedures for devices designed to operate at 270 VDC and 28 VDC respectively.

MIL-HDBK-704-7 270 VDC current interruption

MIL-HDBK-704-7 describes the “Guidance for Test Procedures for Demonstration of Utilization Equipment Compliance to Aircraft Electrical Power Characteristics, 270 VDC”. One test required therein is the so-called Power Interrupt Test, according to the HDC201 method. This test procedure can be used to verify whether the 270 V DC utilization equipment functions reliably and maintains its specified performance even during power interruptions. To perform this test, the appropriate input voltage (nominal, low or high) is first applied to the device. The device is then verified to ensure that it meets the power specifications. The power supply is then switched off for 50 ms and then restored. Finally, the device is tested again to ensure that it meets the power specifications. EA’s bidirectional DC power supplies with autoranging function meet these demanding requirements. The DC power supplies, which deliver up to 30 kW, have very low EMC emissions and feature galvanically isolated USB, Ethernet/LAN or GPIB interfaces.

EA advantages:

- Output voltage up to 2000V

- Power output up to 30 kW

- High power density

- Digital control

- Low EMC

- Experience in the industry

Products used in aviation

MIL-HDBK-704-8 28 VDC standard voltage transients

MIL-HDBK-704-8 describes the “Guidance for Test Procedures for Demonstration of Utilization Equipment Compliance to Aircraft Electrical Power Characteristics, 28 VDC”. One test required therein is the Normal Voltage Transients Test, according to method LDC105. This test procedure can be used to verify whether devices for use with the 28 V DC power supply function reliably and maintain their specified performance even during power interruptions. During this test, the power supply must output voltage transients of up to 70 VDC. After being subjected to the voltage transients, the device is tested to ensure that it meets the performance specifications. EA’s bidirectional DC power supplies meet these demanding requirements with a built-in function generator. This is necessary to generate the required transients. The DC power supplies, which deliver up to 30 kW, have very low EMC emissions and feature galvanically isolated USB, Ethernet/LAN or GPIB interfaces.

EA advantages:

- Power output up to 30 kW

- High power density

- Arbitrary waveform and function generator

- Digital control interface

- Low EMC

- Experience in the industry

Contact form

You need more information or an individual offer? Simply send us your request via the contact form.